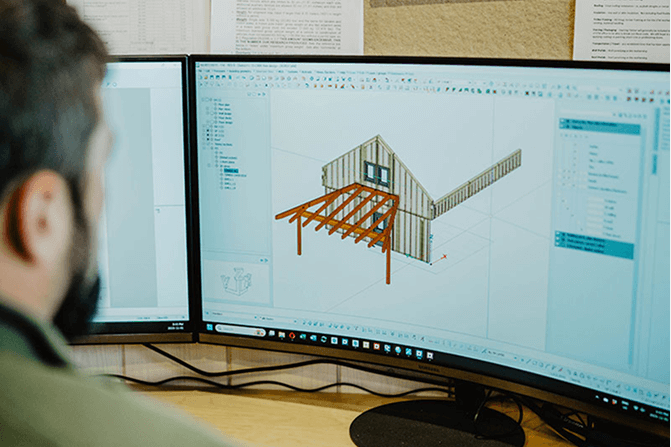

Design

Using industry-leading software tailored specifically for prefabrication and timber design, we’re able to create immersive 3D walkthroughs, and ‘build’, before we build. Our team’s broad experience with this system allows us to confidently conceptualize, design, and manufacture within our quality-controlled facility — then ship and install your project anywhere in the world.

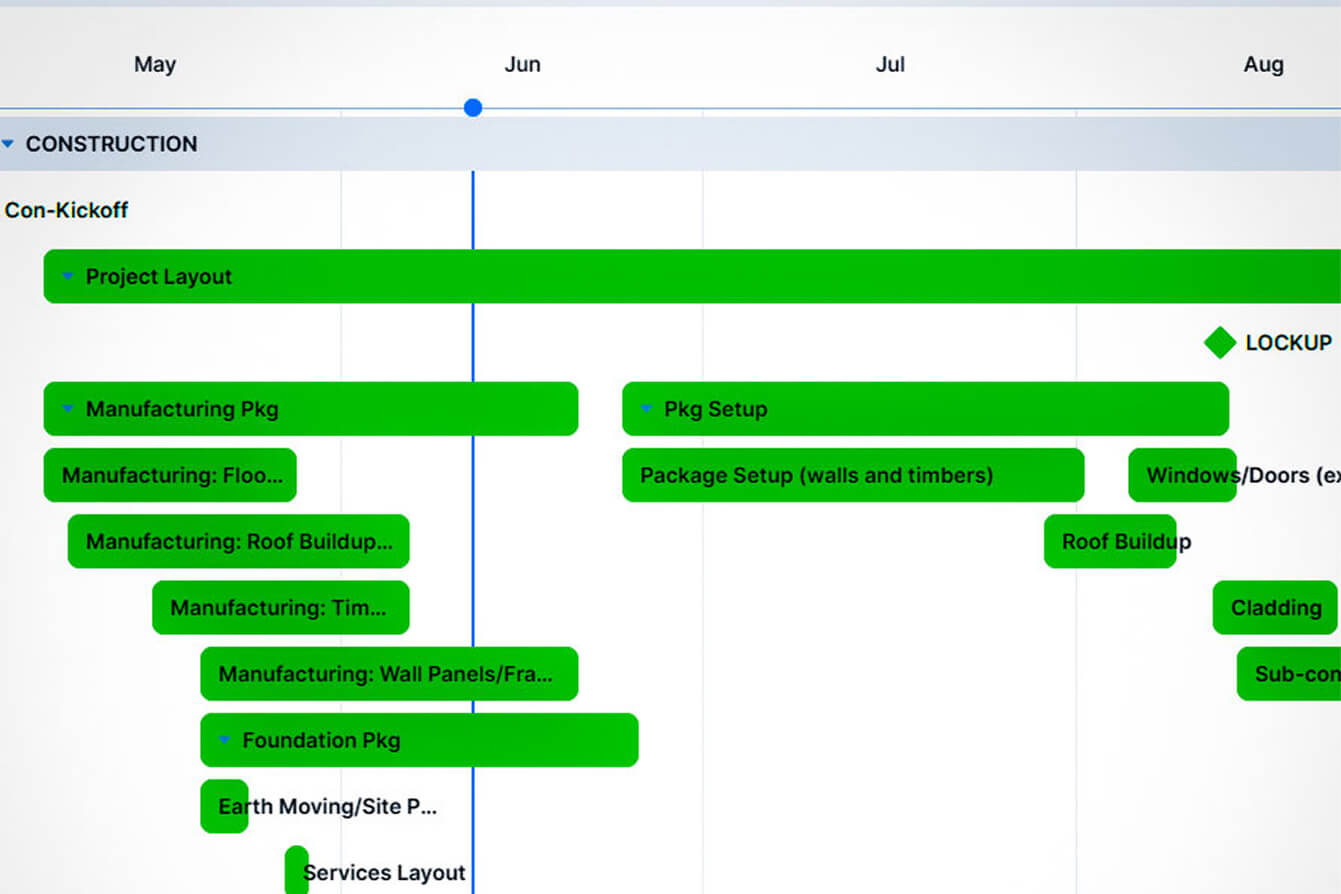

Planning

Methodical planning is a key driver of our efficiency and project success — working closely with clients to bring their vision to life through form and function. Our Virtual Design and Construction Planning lets you preview the finished project before it ever reaches the cutting floor. Our preconstruction support helps ensure the design is practical, cost efficient, and build-ready.

Pre-fabrication

Conventional on-site construction often involves cutting and assembling raw materials in uncontrolled environments, exposing them to moisture, temperature swings, and site-related inefficiencies. This traditional approach introduces avoidable risks and inconsistencies in quality.

By manufacturing components in a climate-controlled facility, we maintain tighter tolerances, protect material integrity, streamline sequencing, and minimize waste — all of which contribute to greater build efficiency and superior end-product performance.

Assembly

Assembly is where everything comes together — the moment when prefabricated components transition from shop drawings to a standing structure. Thanks to our in-house Virtual Build Planning and a skilled team with hands-on experience, we’re able to streamline this process significantly.

By resolving complexities in the digital phase and controlling quality throughout fabrication, site assembly becomes faster, safer, and more predictable — often completed in days rather than weeks or months.

“For the past decade, we’ve had the pleasure of working with Smith Timber Works. As structural engineers who specialize in the design and engineering of timber frame structures, we have occasion to work with many timberframers through-out North America. STW is one of our preferred firms to work with as they, like us, take their work very seriously, but not themselves. They do great work, but don’t rest on their laurels, and are always striving to do better.”